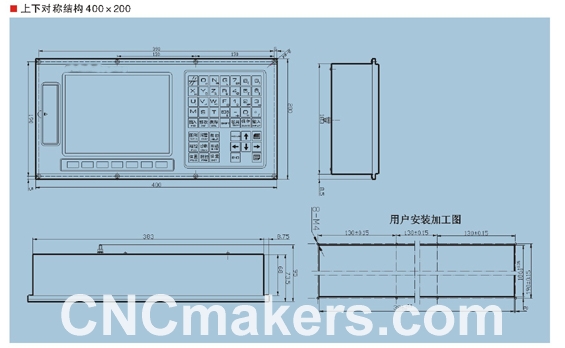

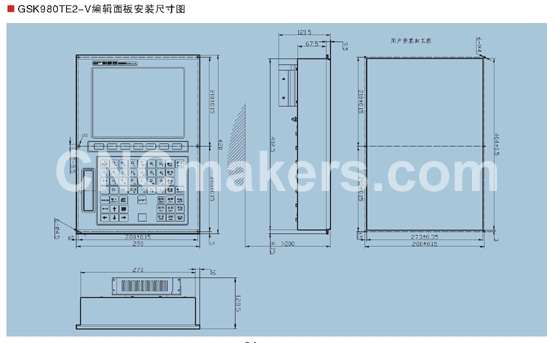

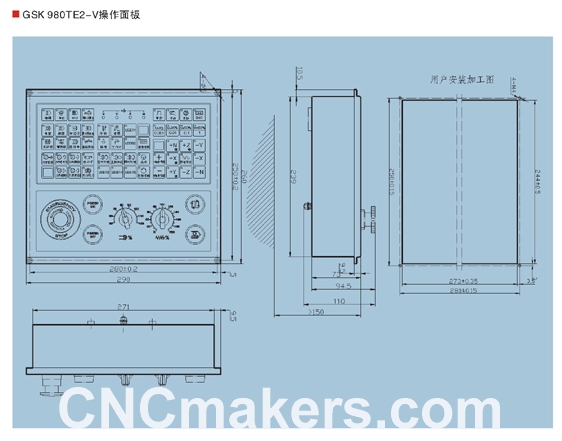

GSK980TE2 including horizontal and vertical mounting structure, GSK980TE2-H and GSK980TE2-V from CNCmakers. GSK980TE2 is Ethernet bus type lathe CNC system, adaptation slant bed turning machine, with processing efficiency and high precision, it is easy to learn. Supports GSK-LINK Ethernet bus, absolute 130 000 line encoder, servo turret and four-station turret, etc. it has three-state switch and Cs-axis control, supports graphics (template) programming function.

2)AC servo spindle adaptable with continuous positioning. 3)Support quadratic curve interpolation , interpolation ellipse , parabola interpolation function , with a variety of complex fixed cycle. 4)Support metric/imperial programming with automatic chamfering , C tool compensation , macro , automatic tool compensation function. 5)8.4 -inch color widescreen LCD display , support for Chinese/English display. 6)Front RS232 communication interface , front USB port, support U disk file operations and software upgrades. 7)Support MPG handwheel,external MPG pendant and servo turret. 8)With prompted alarm help tips, for easier troubleshooting. 9)Security features, including protective doors, three-color lights, emergency stop,hardware stroke limit , software limit detection. 10)Support GSK-LINK Ethernet bus function , easy connection, scalability,support for 17 absolute encoder , high precision, no need to return zero, powerful servo debugging tools can adjust servo parameters on the CNC. 11)Simplify the programming process , support graphics template programming (optional) and physical analog processing functions. 12)With PLC control module and the PLC axis function (supports up to 16 axes), open interactive features , more suitable for completecated machine retrofitting (optional ).

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|