I represents a type of steel: belongs to carbon steel

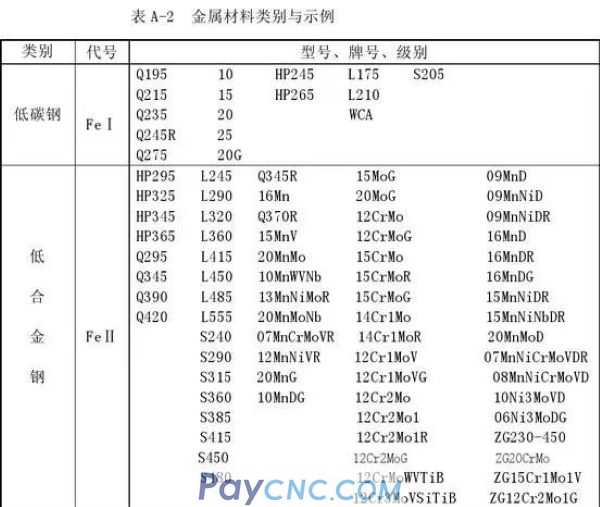

FeⅠtype (carbon steel): Q235, 20#, 20g, 20R, L210, S205, HP265, etc.

I represents a type of steel: belongs to carbon steel

FeⅠtype (carbon steel): Q235, 20#, 20g, 20R, L210, S205, HP265, etc.

Steel with a carbon content of less than 1.35% (0.1%-1.2%), except for iron, carbon and impurities such as silicon, manganese, phosphorus, and sulfur within the limit, without other alloying elements. The performance of carbon steel mainly depends on the carbon content.

As the carbon content increases, the strength and hardness of the steel increase, and the ductility, toughness and weldability decrease. Compared with other steels, carbon steel is the first to be used, with low cost, wide performance range and the largest amount. Suitable for water, steam, air, hydrogen, ammonia, nitrogen and petroleum products with a nominal pressure of PN≤32.0MPa and a temperature of -30-425℃. Commonly used grades are WC1, WCB, ZG25 and high-quality steel 20, 25, 30 and low alloy structural steel 16Mn

Second class steel

Ⅱ represents the second type of steel: belongs to low alloy steel

FeⅡ (low alloy steel): 16MnR, 12Cr1MoV, 20MnMoD, S240, L245, HP295, etc.

Alloy steels with total alloying elements less than 5% are called low alloy steels. Low alloy steel is relative to carbon steel. It is based on carbon steel. In order to improve one or several properties of steel, one or several alloying elements are intentionally added to steel. The amount of alloy added exceeds When carbon steel has the general content of normal production methods, this steel is called alloy steel.

When the total amount of alloy is less than 5%, it is called low alloy steel. The alloy content between 5-10% is called medium alloy steel; those with more than 10% are called high alloy steel.

Class III steel

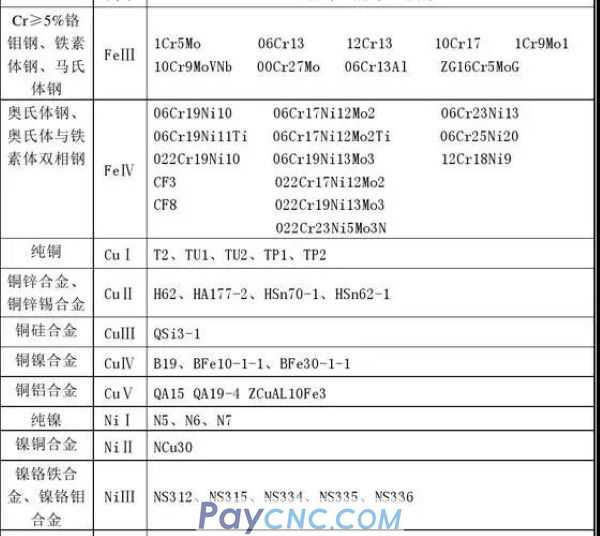

Ⅲ represents three types of steel: martensitic stainless steel, ferritic stainless steel, chromium molybdenum steel

FeⅢ type (martensitic, ferritic stainless steel): 1Cr5Mo, 0Cr13, 1Cr17, 1Cr9Mo, etc.

The standard martensitic stainless steels are: 403, 410, 414, 416, 416(Se), 420, 431, 440A, 440B and 440C, which are magnetic; the corrosion resistance of these steels comes from "chromium", which ranges from 11.5 to 18%, the higher the chromium content, the higher the carbon content is required to ensure the formation of martensite during heat treatment. The above-mentioned three types of 440 stainless steels are rarely considered as applications that require welding. Fill metal is not easy to obtain.

Ferritic stainless steel (400 series) contains 15% to 30% chromium and has a body-centered cubic crystal structure. This type of steel generally does not contain nickel, and sometimes also contains a small amount of Mo, Ti, Nb and other elements. This type of steel has the characteristics of large thermal conductivity, small expansion coefficient, good oxidation resistance, and excellent stress corrosion resistance. It is mostly used for making atmospheric resistance. , Water vapor, water and oxidizing acid corroded parts.

The price of ferritic stainless steel is not only relatively low and stable, but also has many unique characteristics and advantages. It has been proved that in many application fields where only austenitic stainless steel (300 series) can be used, ferritic stainless steel is an extremely An excellent alternative material, ferritic stainless steel does not contain nickel. The main elements are chromium (>10%) and iron. Chromium is a particularly corrosion-resistant element for stainless steel, and its price is relatively stable.

Four types of steel

Ⅳ represents four types of steel: austenitic stainless steel, duplex stainless steel

FeⅣ type (austenite, duplex stainless steel)

Austenitic stainless steel refers to stainless steel with an austenitic structure at room temperature. When the steel contains about 18% Cr, 8%-10% Ni, and about 0.1% C, it has a stable austenite structure.

The austenitic chromium-nickel stainless steel includes the famous 18Cr-8Ni steel and the high Cr-Ni series steel developed by adding Cr and Ni content and adding Mo, Cu, Si, Nb, Ti and other elements on this basis.

Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but its strength is low. It is impossible to strengthen it through phase transformation. It can only be strengthened by cold working. If elements such as S, Ca, Se, Te, etc. are added, it has good properties. Machinability.

Duplex Stainless Steel (DSS) refers to stainless steel with ferrite and austenite each accounting for about 50%. Generally, the content of less phases needs to be at least 30%. In the case of low C content, the Cr content is 18% to 28%, and the Ni content is 3% to 10%. Some steels also contain alloying elements such as Mo, Cu, Nb, Ti, and N.

This type of steel has the characteristics of austenitic and ferritic stainless steel. Compared with ferrite, it has higher plasticity and toughness, no room temperature brittleness, and significantly improved intergranular corrosion resistance and welding performance, while still maintaining iron The 475℃ brittleness, high thermal conductivity, and superplasticity of element stainless steel.

Compared with austenitic stainless steel, it has high strength and significantly improved resistance to intergranular corrosion and chloride stress corrosion. Duplex stainless steel has excellent pitting corrosion resistance and is also a nickel-saving stainless steel.

There are also some special materials on the welder's certificate:

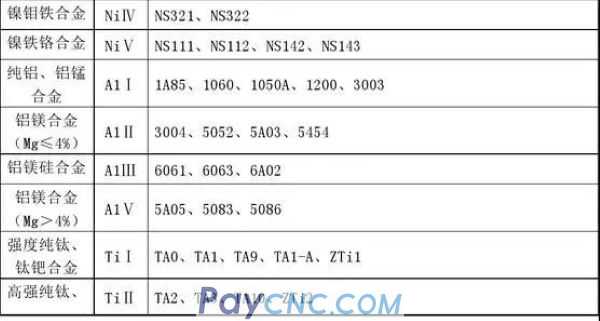

Copper and copper alloy: CuⅠ~ CuⅤ

Nickel and nickel alloy: NiⅠ~NiⅤ

Aluminum and aluminum alloy: AI~AIⅤ

Titanium and titanium alloys: TiⅠ~TiⅡ 0Cr18Ni9Ti, 0Cr19Ni13Mo3, 0Cr25Ni20, 1Cr23Ni18, etc.

Welding method code

AW (arc welding): arc welding;

TIG: Tungsten argon arc welding;

SMAW (shielded metal arc welding): electrode arc welding;

Ws: full argon arc welding;

GTAW+SMAW: base for manual argon tungsten arc welding + manual arc welding cover;

GTAW (gas tungsten arc welding): gas tungsten arc welding (solid core or flux cored wire);

Ws+Ds: Argon arc base + arc cover;

FCAW: (flux cored arc welding): flux cored arc welding;

ESW: (electroslag welding) electroslag welding;

FCW-G: (gas-shielded flux cored arc welding): gas-shielded flux cored arc welding;

FCAW: CO2 shielded welding with flux cored wire;

SAW: (submerged arc welding): submerged arc welding;

GMAW: CO2 semi-automatic welding;

MIG: melting pole semi-automatic inert gas shielded welding;

OAW (oxy-acetylene welding);

FW: (flash welding) flash welding;

EGW: vertical gas welding;

FRW: (friction welding) friction welding;

LBW: (laser beam welding) laser welding;

EXW (explosion welding) explosion welding.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|