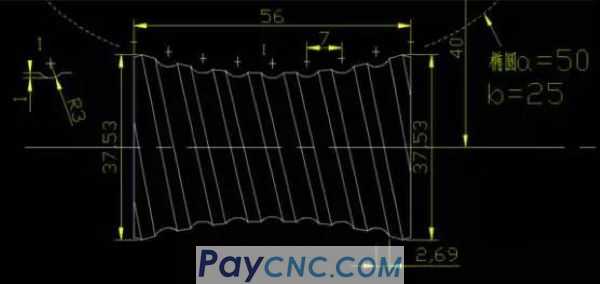

I don’t consider the rationality of my own design

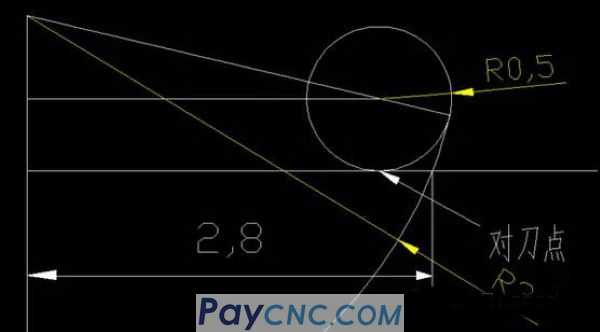

Let’s take a look at the error caused by using a ball knife or a sharp knife to make the tip arc (actually, I don’t know how to use G42 here. I look forward to the explanation of the knife compensation by Master Guigu)

Assuming that this is a tool tip of R0.5, if you add C-type tool compensation, the path of the tool is the same as the above picture, but if you don’t add it, how to eliminate the error, first look at the center of the tool tip arc, which is the top one in the picture above The trajectory taken by the green line is an arc of R2.5. Then look at the tip of the tool, which is A (tool setting point). The arc from A to B is also an arc of R2.5 as above. , The arc of R3 allows the tool tip to follow the arc of R2.5. The focus here is the coordinates of the starting point and end point of the arc of the tool tip.

Looking at the first picture, the starting point of R3 is Z2.69, so here I am taking Z2.8, then where is the real starting point of the tool tip, as shown in the figure above, if there is a drawing software such as CAD, it can be directly measured , If not, you can count it like this #1=SQRT[25*25-[SQRT[9-2.8*2.8-0.5]²]=2.433 Macro operation does five more operations. This is an example. This solves the program :

T0101

M3S300

G0X45Z14

#1=2.433 Z starting point of arc

N1#2=SQRT[2.5*2.5-#1*#1] X coordinate of arc

G0X[40-#2*2]Z[14+#1] positioning

#3=28 The Z coordinate of the starting point of the ellipse, used for calculation

N2#4=2*25*SQRT[1-#3*#3/2500] X coordinate of ellipse

#5=80-#4-#2*2+4 Actual programming X coordinate

#6=#1+#3-28 Actually programmed Z coordinate, here subtracting a 28 means that the starting point coordinate of the ellipse is set to 0

G32X#5Z#6F7

#3=#3-7 Let me talk about it, I have always used one pitch as the pitch. I saw Master Guigu used 1. I haven't tried it. I live to learn and learn. Of course, the smaller the pitch. The more precise

IF[#3GE-28]GOTO2 Let’s talk about it here. The end point of the ellipse in the figure is 28. If GT is set here, then G32 will stop when the car reaches -28, leaving a slot

G0X50

Z14

#1=#1-0.05

IF[#1GE-2.433]GOTO1

G0X200

Z200

M30

This method is basically the same as that of Master Guigu, so I won’t go into details. The above program is not available for all systems, such as Guangshu 980. If you do it like that, the knife will stop at each step and generate a Slot (It should be because of computing power. This is what I tried before.)

Imagine first using a R3 forming knife to complete the car

Looking at the center of the tool tip, the trajectory is also the elliptical trajectory. Any point on the tool tip is the elliptical trajectory, so just locate the starting point and use the incremental value to do it. The effective length of the ellipse is 56, and the pitch is 7,

Then calculate the X value of the ellipse at each pitch.

When the ellipse Z=28, which is the starting point, X=2*25*SQRT[1-28*28-2500]=38.57;

X=34.62 when Z=21;

X=32 when Z=14;

X=30.49 when Z=7;

X=30 when Z=0;

X=30.49 when Z=-7;

X=32 when Z=-14;

X=34.62 when Z=-21;

X=38.57 when Z=-28;

X=44.29 when Z=-35;

With these, you know the increment value

program:

T0101

M3 S300

G0 X45 Z14

#1=2.433

N1 #2=SQRT[2.5*2.5-#1*#1]

G0 X[40-#2*2] Z[14+#1]

#5=38.57-#2*2+4

G32 X#5 Z#1 F7

G32 U-3.95 W-7 F7;

G32 U-2.62 W-7 F7;

G32 U-1.51 W-7 F7;

G32 U-0.49 W-7 F7;

G32 U0.49 W-7 F7;

G32 U1.51 W-7 F7;

G32 U2.62 W-7 F7;

G32 U3.95 W-7 F7;

G32 U5.72 W-7 F7;

G0X50

Z14

#1=#1-0.05

IF[#1GE-2.433]GOTO1

G0X200

Z200

M30

I designed a picture, you can edit it if you are interested

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|