01

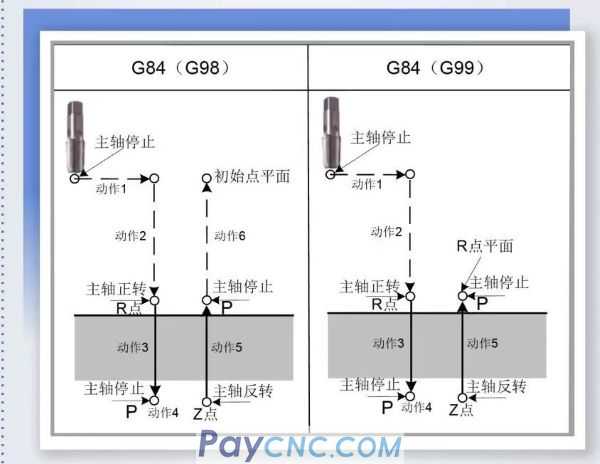

The rotation and feed of the spindle are always synchronized during the rigid tapping cycle. In rigid mode, the control of the spindle motor is a servo motor, which can realize high-speed and high-precision tapping. It can be ensured that the thread will not be buckled or broken teeth without changing the R point.

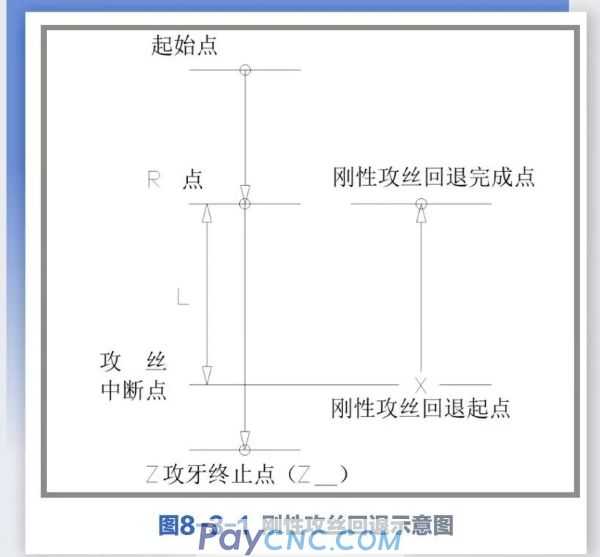

Rigid tapping is a commonly used function in processing. During tapping, the phenomenon of broken cones is relatively common due to reasons such as workpiece clamping accuracy or processing program writing. The rigid tapping retraction function can perform emergency tapping retraction action after an emergency interruption, reset, power off, etc. to return the tapping axis to the tool R point position, and safely withdraw the tool.

The 218MC rigid tapping retract function adopts a more concise way, because when the system performs rigid tapping, the tap may not be retracted outside the workpiece due to power failure or emergency stop. The tap of the knife workpiece comes back, and the rigid tapping retract function is born. The rigid tapping back function is described in detail below:

02 execution process

Eliminate all alarms and put the system into reset state-select MDI operation mode-press the [spindle quasi-stop] button to turn on the rigid tapping and rewind RTNT signal-the system performs retraction with the last tapping parameter-spindle rotation feed axis feed Give-retract to point R (tapping retraction completion point)-rigid tapping retraction is completed, RTNT signal becomes 0, RTPT tapping retraction completion signal becomes 1- normal operation axis retracts to the starting point.

start up

After being in the reset state, select the MDI mode, press the [spindle quasi-stop] button tapping retract function start signal RTNT conduction is 1, the system begins to perform the rigid tapping retreat action;

carry out

After the rigid tapping retraction is completed, the rigid tapping retraction start signal RTNT is turned off to 0, the rigid tapping retraction completion signal RTNT signal is turned on to 1, the tapping retraction action is terminated, and the system process is reset. Perform other normal operations;

Signal Rigid tapping retraction start signal

RTNT (G062#6)

【Type】Output signal

[Function] This signal informs the PLC that it is in the rigid tapping retraction mode

[Output condition] RTNT 1: currently in rigid tapping retraction mode

0: It is not the rigid tapping back method at present

Signal Rigid tapping retraction start signal

RTNT (G066#1)

【Type】Output signal

[Function] This signal informs the PLC that it is in the rigid tapping retraction mode

[Output condition] RTNT 1: currently in rigid tapping retraction mode

0: It is not the rigid tapping back method at present

03 Conclusion

Through the above description, you can quickly understand the rigid tapping retraction function, effectively provide an intuitive and concise display interface, this function will automatically store the last executed tapping processing information, after turning on the tapping back signal, the system according to the stored The information executes the retraction action of the corresponding rigid tapping cycle, and retracts the tap tapped into the workpiece to the R point position of the tapping command, thereby ensuring the stability of processing and debugging.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|