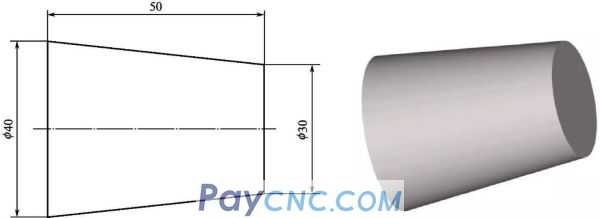

CNC turning processing as shown in Figure 2-1, the outer cone surface, set the blank diameter ϕ42, try to compile a macro program for processing.

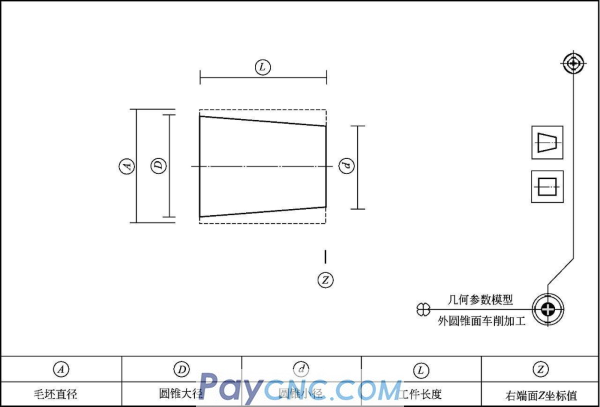

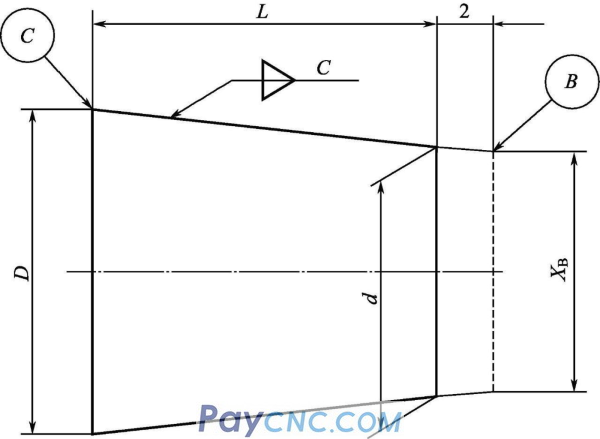

Establish the geometric parameter model of turning the outer cone as shown in Figure 2-2. The blank diameter A, length L, cone diameter D and cone diameter d

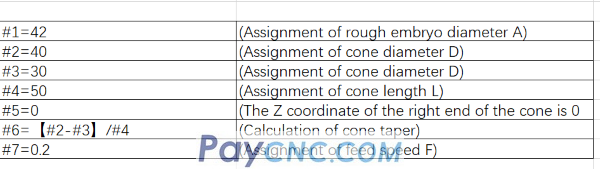

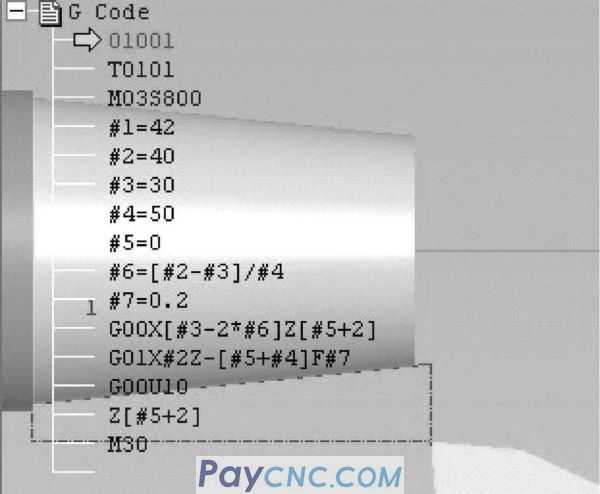

First assign values to the relevant parameters:

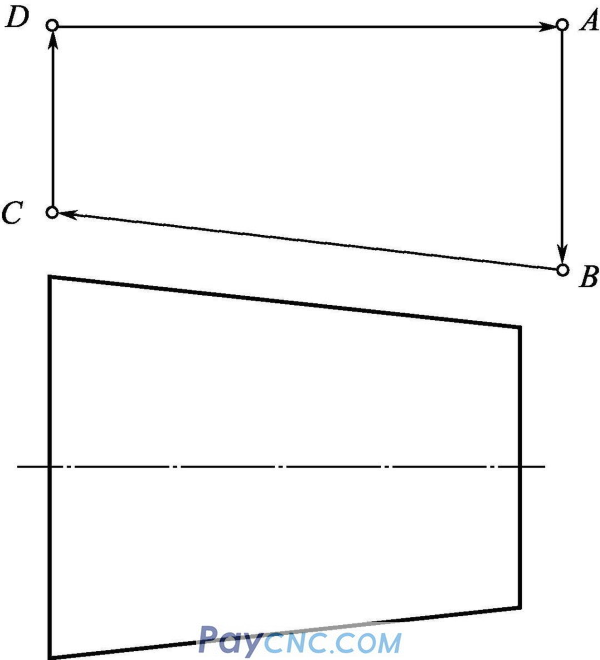

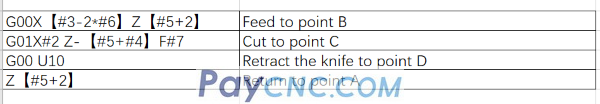

The finishing route is shown in Figure 2-3. A→B→C→D→A. Compile part of the finishing program:

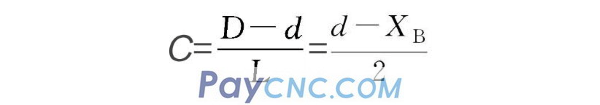

Why is the X value of point B "#3-2*#6"? In Figure 2-4, extend the conical surface by 2mm to point B, and obtain that the cone with the length L on the left is equal to the cone with the length 2 on the right.

Solve the X coordinate value of point B: XB=d-2C=d-2, so the X value of point B is expressed as "#3-2*#6" in the macro program, where #6 is the value of the taper of the cone.

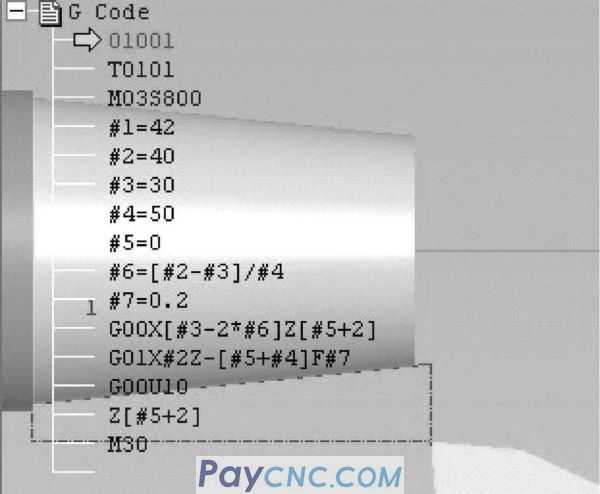

"Assemble" the two parts of the program of variable assignment and finishing to complete the finishing with a macro program. The results are shown in Figure 2-5.

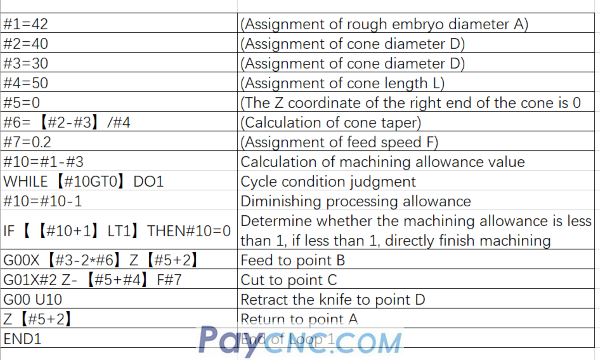

Next, you can translate the trapezoidal route of A→B→C→D→A as shown in Figure 2-3, and perform the rough finishing of the conical surface by layer cutting. Analyzing the geometric parameter model can obtain the total machining allowance as the blank diameter A -Conical diameter d. Using the machining allowance as a variable, the WHILE loop statement is used to compile the machining program as follows. The bold part of the program can be regarded as the program operation part of the three basic parts of the macro program:

Try also to assemble your own program with the three basic parts of the macro program!

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|