|

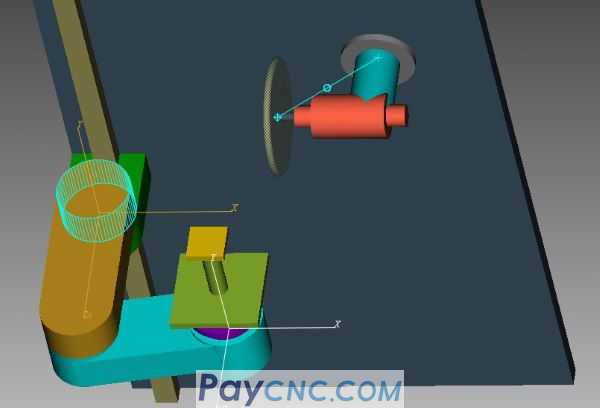

Using Shandong Weida Heavy Industry VMC640 machine tool with GSK 25iMb system machining center to process stainless steel pump body, end cover, gear and other parts, the pumping output end is at a pressure of 3kg and the flow rate is not less than 70L / hour.

solution

Formulate clamping tooling plan and processing technology according to customer's parts;

Recommend and use reliable machining tools;

The dimensional accuracy of each process after debugging is stable within 0.01mm, which meets the design requirements;

Multiple processes can run continuously and normally to meet mass production;

After the production and processing of the parts, other accessories can be assembled to meet customer requirements.

Application effect

The precision of the dimensions of the pump body and end cover is within 0.01mm. Five sets of pumps are tested after the gears and other components are assembled. The output of the pump body is 3L under pressure and the flow rate reaches 90L / hour, which meets customer needs.

Application of GSK25i CNC system in steam turbine blade production line

Supports eight-axis five-link RTCP function;

3 + 2 positioning processing function;

B-spline toolpath adaptive feed technology.

solution

With five-axis RTCP function, it can support the processing of complex parts;

With dedicated 3 + 2 positioning processing function instructions;

B-spline curve can effectively filter and smooth the tool path, improve processing efficiency and surface finish;

Fully closed loop equipped with HEIDENHAIN encoders.

Application effect

The processing time of this part is 7 minutes and 22 seconds, and the overall processing time is 86 minutes, which is about 27% higher than the original processing time;

The surface finish has also been greatly improved to fully meet customer requirements.

Application of GSK25iM CNC system in grinding production line

Joint robotic hand structure, in manual mode, must support multi-axis associated movement;

Simplified programming, need to support teach programming;

Must have interference check function and limit function.

solution

Dedicated articulated robot function, support parallel axis function, realize linear, curved, circular motion of the workpiece;

Easy programming mode, using teach-in programming;

Flexible position switch, perfect hardware and software limit function, form protection and anti-collision function for machine tools.

Application effect

Greatly increased grinding efficiency and reduced labor costs;

Improved grinding accuracy.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|