01 To use the indexing table, it is necessary to modify the parameter K14.0 to 1 to be effective, as shown in Figure 1;

The indexing table release code M11, the clamping code is M10;

When using the indexing table, if the indexing table is clamped, the fourth axis can be rotated in any way. When the indexing table is released, the program can perform the fourth rotation, and use parameter K14.3 to determine whether to allow After opening, use the hand wheel to manually rotate the fourth axis, as shown in Figure 2;

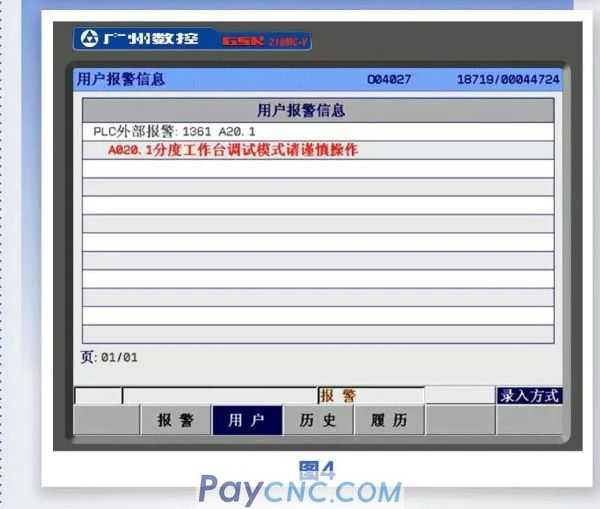

If you need to debug the fourth axis rotation, modify K14.7 to 1, as shown in Figure 3, enter the working indexing table debugging mode, PLC alarm A20.1 appears, as shown in Figure 4, the alarm is ignored, at this time the manual handwheel mode can be used Freely move the fourth axis without interlocking with the loose clamp in-position signal;

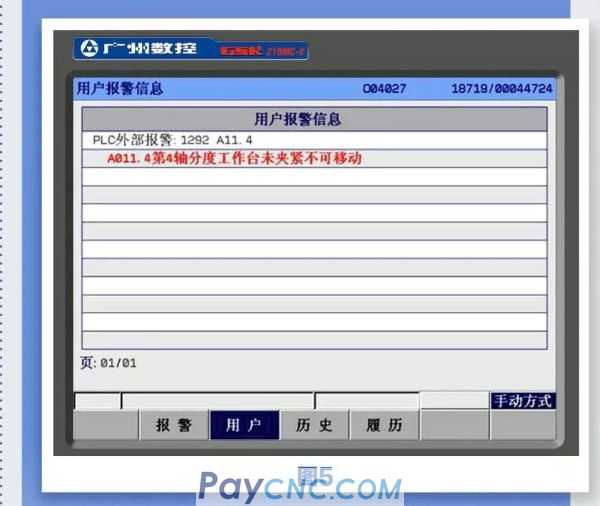

When the indexing table is released, an alarm prompt will appear when moving XYZ. As shown in Figure 5, movement is not allowed. If the user does not need this restriction, modify K14.4 to 1, as shown in Figure 6;

Automatic clamping of the indexing table, using the automatic clamping mode of the indexing table can still use the M10 and M11 codes for clamping; the automatic clamping device of the working table must set the fourth axis to the rotation axis and four linkage, need Set the following parameters; set K14.0 to 1, set K14.1 to 1, as shown in Figure 7.

The indexing table can be installed without loosening and clamping in place detection switches. When the switch is not installed, the parameter K14.2 must be modified to 1, as shown in Figure 8, when the switch is not installed, the timers T0036 and T0037 are used as virtual releases. In-position and clamping in-position delay detection, the user needs to set this time according to the speed of the mechanical action, the default is 500ms, as shown in Figure 9;

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|