01 Tool magazine installation and related PLC parameter settings

Operation purpose: to match the ladder diagram with the configuration of the tool magazine.

The requirements for the machine tool when this ladder diagram is equipped with a bucket-shaped tool magazine:

The machine tool has a spindle tool automatic clamping/loosening device, and the automatic clamping/loosening device is equipped with a normally open in-position detection switch.

The spindle has a positioning function, and the positioning angle can be adjusted.

The capacity of the tool magazine is less than 100.

(The setting value of D100 must be less than 100 and the same as the setting value of CTR100, otherwise an exception will occur.

For example: when D100=16, the data table D001-D016 is valid;

When D100=24, data table D001-D024 is valid. )

The tool magazine can rotate forward and reverse.

The tool magazine has a count switch, a forward in-position detection switch, and a backward in-position detection switch.

The tool magazine has a zero return switch (optional).

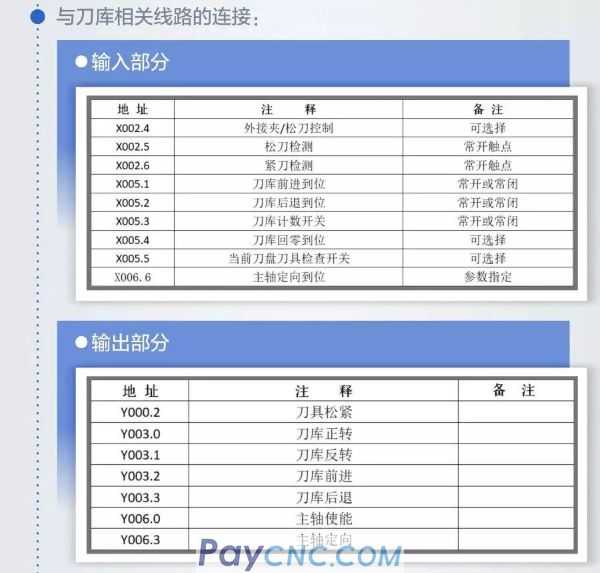

Connection with the relevant lines of the tool magazine:

Precautions

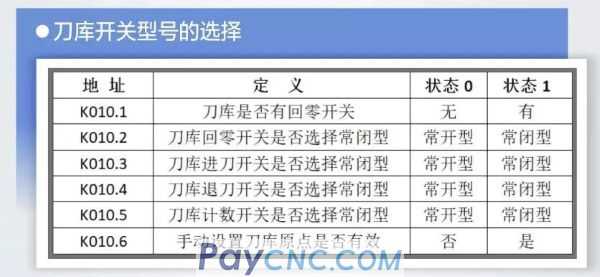

K10.1 and K10.6 must be set according to the actual situation, can not be 1 at the same time.

For example: there is a tool magazine without zero return switch, each detection switch is normally open, and the parameters should be set to:

K010.1=0 K010.2=0 K010.3=0 K010.4=0 K010.5=0

Tool magazine capacity setting:

Re-enter the tool magazine capacity in DATA100 and CTR100.

Precautions

Tool magazine capacity refers to the number of tool sets that weigh the tool magazine.

The setting values of DATA100 and CTR100 must be less than 100.

For example: when the tool magazine capacity is 16, set DATA100 to 16 and CTR100 to 16.

Setting of tool number in the tool magazine:

The data tables D001-D099 respectively correspond to the tool magazine No. 1 to No. 99, the set values in the data tables D001-D099 respectively correspond to the tool numbers in the tool magazine No. 1-99, and D245 refers to the tool number on the spindle.

Precautions

The same tool number (except 0) cannot be set in D001-D099, otherwise an alarm will appear when changing the tool.

The setting range of the tool number needs to meet the requirements set by the parameter 0206, otherwise an alarm will appear when the T code is executed.

For example: when the tool magazine capacity is 16,

If set to 1-16 in sequence in D1-D16, when T8M6 is executed, the No. 8 tool sleeve will be rotated to the tool change position and the tool exchange will be performed;

If it is set to 10, 20.30........160 in D1-D16 in sequence, when T80M6 is executed, the tool sleeve No. 8 will be rotated to the tool change position and the tool exchange will be performed;

If both D1 and D2 are set to 8, an alarm will appear when executing T8M6.

The setting of the time parameter (TMR) related to the tool magazine:

Precautions

The above parameters (TMR) are related to the type of the tool magazine, the rotation speed of the tool magazine, etc. Please set it reasonably according to the performance index of the tool magazine.

Improper setting of the above parameters (TMR) will cause an alarm and make it impossible to change the tool normally.

Through the basic operation of the AF step, the ladder diagram and the configuration of the tool magazine are matched, but the tool magazine still cannot run normally. Through the setting and wiping of the second part below, the tool magazine can be rotated forward and reverse under manual operation Turn, feed, and retract movements to check whether the movement of each step of the tool magazine is normal.

02 Manual and zero operation of the tool magazine

Operation purpose: check whether each step of the tool magazine is normal.

The specific steps are as follows:

The tool magazine is effective.

The default state of the system is to use Ladder01.grp ladder diagram, which is the ladder diagram of the bucket-shaped tool magazine. Bit parameters NO:53#0=1, NO:53#1=0, NO:53#2=0, NO:53#3=0.

The PLC ladder parameter K001.0 is set to 1.

Determination of the rotation direction of the tool magazine:

In the manual mode, press the counterclockwise button of the tool magazine, the tool magazine rotates in the direction of increasing tool number, press the button of the tool magazine clockwise, the tool magazine rotates in the direction of decreasing tool number, if the opposite phenomenon occurs, the tool magazine count will be disordered , Leading to tool exchange error, adjusting the phase sequence of the rotary motor of the tool magazine can solve this problem.

Return to zero operation of tool magazine:

The zero return operation of the tool magazine is divided into two cases with a zero return switch and no zero return switch

When the tool magazine has a zero return switch: Press the tool magazine to return to zero in the "mechanical zero return" mode. When the "tool magazine zero return indicator" is on, the zero return is completed (the light flashes to indicate that the tool magazine is returning to zero).

When the magazine does not have a zero return switch, set the magazine zero point and follow the steps below:

1. In manual mode, press the tool magazine counterclockwise or tool magazine clockwise button to rotate tool magazine No. 1 to the position where the tool is exchanged.

2. In the entry mode, set K010.6 to 1.

3. In the mechanical zero return mode, press the tool magazine to return to zero until the "tool magazine return to zero indicator" lights up.

4. Set K010.6 to 0.

03 Correct handling method of emergency stop, power failure and reset, alarm during tool magazine operation

When the tool change is entered in the input mode or the tool is changed in the automatic mode, when the tool magazine is in the forward limit position, the spindle is lowered to the gripping position, the tool has been clamped, and the tool magazine will retreat but not retreat, such as emergency stop, power failure or alarm 1. Reset, if you want to continue to use the machine tool, you must press the tool magazine back (back) button on the system to exit the tool magazine in manual mode, make the tool deviate from the current tool magazine card position, and then use (note: do not release the spindle at this time , Lift the Z axis to exit the tool magazine, so that the tool magazine corresponding to the current spindle is equipped with a tool, leaving a hidden danger of tool collision for the next tool change).

When the tool change is entered in the input mode or in the automatic mode, when the tool magazine is in the forward limit position, the spindle has released the tool, and the Z axis will not be lifted, or the tool tray has not been rotated after the Z axis is lifted, such as emergency stop, Power off or alarm, reset, if you want to continue to use the machine tool, you must press the "loosening knife" button on the spindle in manual mode to make the tool loose, then lift the Z axis manually or manually to reach the safe position, press The tool magazine back (back) key on the system exits the tool magazine. (Note: the tool magazine corresponding to the current spindle is equipped with a tool, there is no tool on the spindle, and the system should display "T0000") It can be used normally.

04 end

When commanding tool change in the input mode or tool change in the automatic mode, when the tool magazine is at the forward limit position, the Z axis has been lifted at the first reference point, and the cutter head is rotating, it may be in case of emergency stop, power failure or alarm, reset The muzzle where the current tool number and the actual tool number are inconsistent appears, the system appears: "1218 tool magazine abnormal stop and reconfirm tool number" "1244 tool change abnormal stop to ensure that the tool magazine is normal" light alarm, if you want to continue to use, you must manually Next, press the tool magazine back (back) button on the system to exit the tool magazine. The tool magazine will return to zero and set the spindle tool number and tool magazine tool number again, then it can be used normally.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|