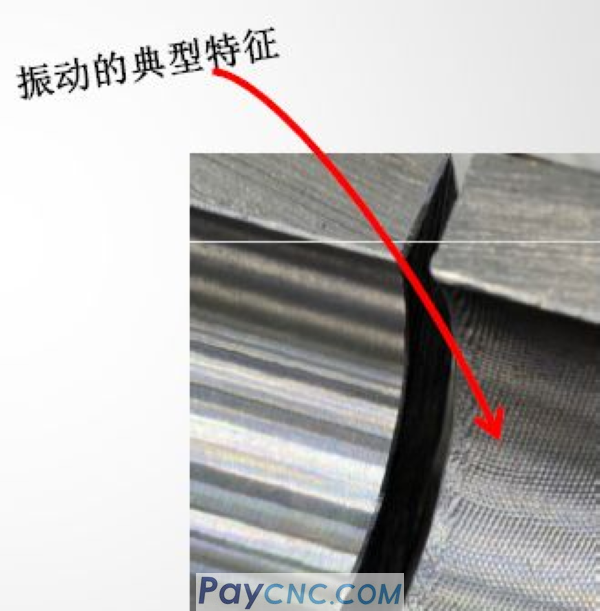

Various problems will be encountered in the CNC machining process, such as the vibration knife during the cutting process, which causes the parts to have vibration patterns, and the tool is easy to jump the blade.

If you encounter this kind of problem, how to solve it? Welcome to leave a message and share your precious experience.

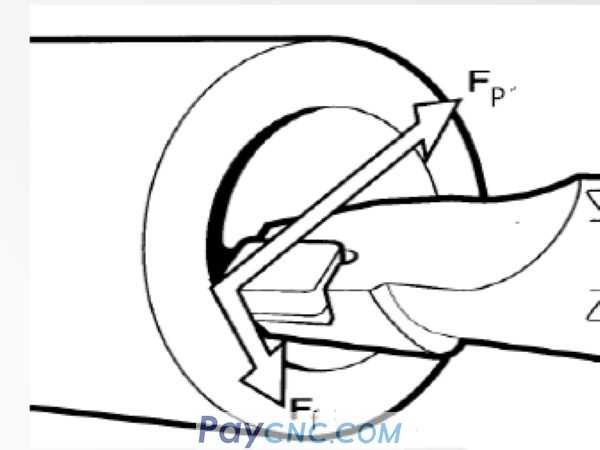

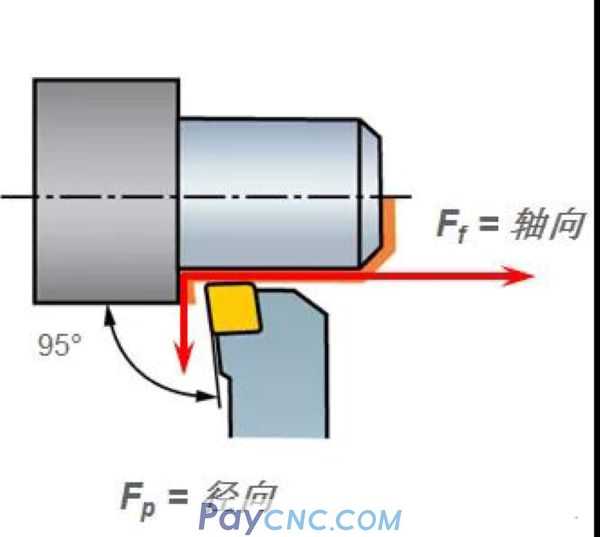

The tool will produce a component force (Fp) in the radial direction when processing the workpiece, as shown below:

When a force is applied, if the tool has insufficient rigidity, the tool body will be deformed, which will produce a deviation in the direction of the force and a displacement.

The tool has a displacement, so the depth of the knife is reduced, the force is also reduced, and the resulting displacement is also reduced.

The resulting displacement becomes smaller, the tool moves in the opposite direction of the force, so that the depth of the knife becomes larger, and the cutting becomes larger.

This is like comparing a knife to a slender wooden stick with one end fixed and the other end stressed, so that the end away from the unfixed end will deflect and rebound.

In this way, during the machining process, the constantly changing cutting force acts on the tool and the workpiece, thereby generating vibration.

Then we can see that there are two directly related factors that produce vibration:

First, the strength of the knife body itself.

Second, the size of the cutting force.

Of course, it is also related to other factors, such as the strength of the workpiece (the workpiece will also produce displacement), machine tools, fixtures, processing parameters, etc., and Brother will not start the analysis.

Today this article only gives you a solution from the above two points.

One, the strength of the knife body itself

The strength of the knife body itself is easy to understand. The thicker the shorter, the stronger the strength, so if you want to solve the vibration problem in this direction, then keep the knife body short and thick, it will definitely solve the problem. . If the processing length is required, then the following issues should also be noted.

1. The extension length of the steel cutter bar is controlled within 3 times the diameter.

2. The extension length of the heavy metal cutter bar is controlled within 6 times the diameter.

3. If it needs to be as long as possible, use a shock-absorbing blade.

Second, the size of the cutting force

Cutting force, this is better understood, the smaller the cutting force, the smaller the vibration. So from a tool perspective, you can choose the right tool from the following two aspects, and the effect will be immediate.

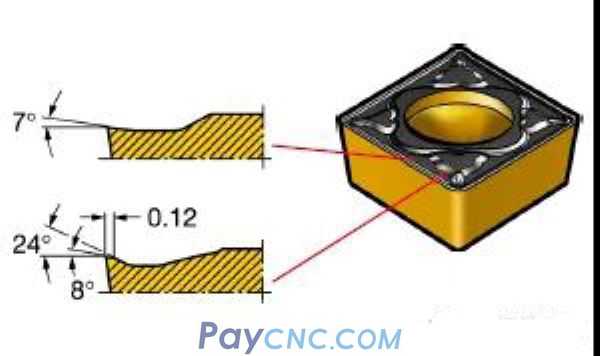

1. Tools with large rake angle and small edge width.

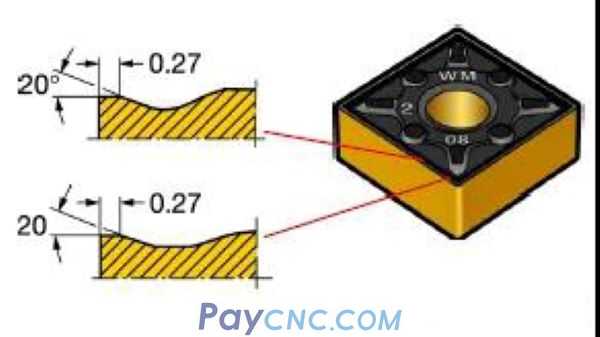

Regarding the width of the cutting edge of the tool, many friends said that they did not know, and the specific concept will not be explained. A picture is worth a thousand words, as shown in the following figure:

The two types of blades in the above figure have rake angles of 20 degrees and 24 degrees, and the edge widths are 0.27 and 0.12, respectively.

In other words, the larger the rake angle, the smaller the edge width means the sharper the tool, the smaller the cutting force during cutting.

In addition, the width of the cutting edge of the tool is very important. It directly determines the size of the feed F during programming. There is time to share about the selection of cutting parameters.

2. The main angle of cutter

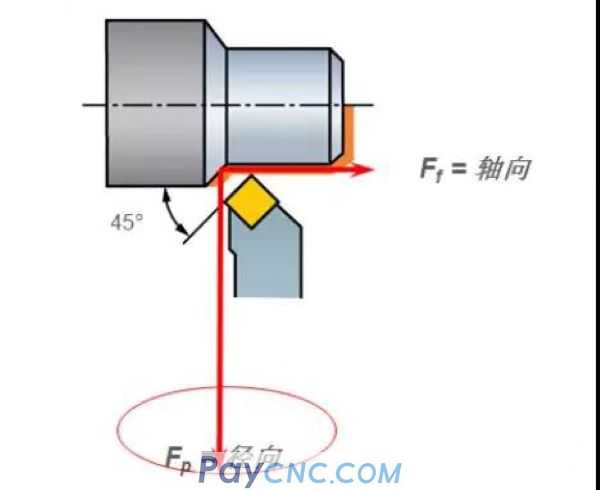

The tool will be subjected to two forces during the cutting of the part, the axial and radial cutting forces.

For example, as shown in the following figure:

The picture above shows a cutter with a 45° main declination angle. The length of the red arrow indicates the magnitude of the force in this direction, that is, the radial force is greater than the axial force.

The picture above shows a tool with a 95° lead angle. The length of the red arrow indicates the magnitude of the force in this direction, that is, the radial force is less than the axial force.

That is to say, the magnitude of the tool's main declination angle directly determines the magnitude of the radial cutting force. The larger the tool's main declination angle, the smaller the cutting force received in the radial direction, and the smaller the main declination angle, the greater the cutting force received in the radial direction.

As shown below:

The above three common tool main angles are: 90°, 75°, 45°. The smaller the main declination angle, the greater the radial force, and the greater the tool vibration tendency.

Well, today’s dry goods will be shared here. If you take a look at it and feel that you know this knowledge, or understand it yourself, and don’t think in depth, then it is difficult for you to learn something and make achievements.

Remember, knowing that it does not mean it will!

Army brother, the dry goods I shared, if you look at it in general, it seems that there is nothing tall, but if you think about it carefully, if you make a difference, everything is completely different.

for example:

When machining deep holes, have you encountered the unstable size of the via holes?

what reason?

If you analyze from the perspective of the tool, you should seriously think about the principle of vibration generation at the beginning of the article.

When a force is applied, if the tool has insufficient rigidity, the tool body will be deformed, which will produce a deviation in the direction of the force and a displacement. This explains why the dimensions are unstable.

You further think that when the tool is cutting the part, the part will also be subjected to force. If the rigidity of the part is insufficient, the part will also generate displacement and deflection.

If the tool is sharp, because it is far from the end of the clamping, the part deflection is large when the cutting force is applied, then the cutting will be more, if the hole is processed, the size of the hole will be large... This is the part of the master commonly known as the processed belt.

How to solve, if the part itself is not rigid enough, it is difficult to solve the clamping, then from the perspective of the tool, such as selecting a tool with a larger main declination angle, reducing the force in the radial direction of the part, thereby reducing the deflection of the part due to insufficient rigidity ,shock…….

Well, people in this era are very impetuous. Many people have a look at the dry goods shared by military brothers, and then they will wait for the next new article. In this way, no matter how much they have watched, they have not really grown up. why?

1, no deep thinking

Those who engage in our business are more professional. The important thing is not how much you have seen and understood, but how much you have thought deeply, how much you have understood, and how much you have used.

2. No systematics

Knowledge can be said to be connected one by one, and the rings are all connected. The monkey helps the corn-like learning. It takes a lot of east and west to pay a lot, and it has little effect in the end, which is very worrying.

So how to study systematically and think deeply?

Take UG software programming as an example:

Although there are thousands of knowledge points in the parameter commands of UG, this is a fact, but I have constructed my own set of theoretical system, which is simplified and complicated, and I leave it to others and present it to others simply. This set of theoretical systems is described in detail in the article "Building the Four Major Systems of UG and Letting You Play with UG Software Programming".

For another example, macro programming, many people think that macro programming is very mysterious and very difficult to learn. At the same time, in today's popular software programming, it seems that there is no need to learn. In fact, when you think deeply, you will find that all fields are actually Are the same.

For example, [Plane Milling] in UG software programming, I summarized two features:

1. [Face milling] is not defined by three-dimensional entities to define the processing geometry, but the boundaries created by edges or curves to determine the processing area.

2. 【Face Milling】The tool path from the first layer to the last layer, except for the depth of the tool path of each layer, the shape is strictly the same as the previous or next tool path.

Thanks to the second feature of [UG plane milling], I made a [macro program] hierarchical programming framework, a ready-made programming framework, and applied the framework around the ideas taught by the army brother. Write your own macro program!

When you have mastered [Macro Program] layered programming, you will suddenly realize that learning UG programming is not the feature of UG plane milling! When you learn UG, when you come to play macro programming and think deeply, you will dig out many common places.

How fun this is, you will find that all areas are actually the same, everything has become very simple.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|