The offset display, modification and setting steps of the 218MC system provide customers with a convenient, concise and intuitive operation interface. The following details the offset display, modification and setting steps:

01 Offset display

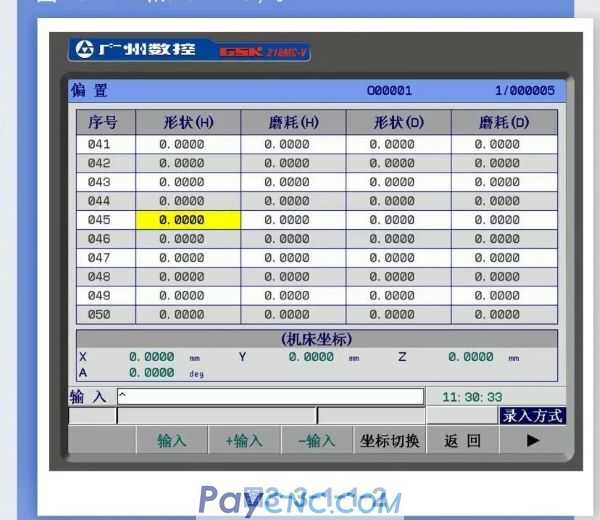

Press【+Offset】soft key to enter the offset display page, the offset interface is displayed as follows (see Figure 3-3-1-1-1).

Press the [+Offset] soft key in the above figure to enter the offset operation interface (as shown in Figure 3=3=1=1=2 and 3-3-1-1-3).

The compensation amount can be directly input or added and subtracted with the value at the current position. Shape (H) represents tool length compensation, wear (H) represents tool length wear, shape (D) represents tool radius compensation, and wear (D) represents tool radius wear. Press [Clear Shape] and [Clear Abrasion] to clear all the values of tool length compensation, wear and tool radius compensation and wear.

02Offset is worth modifying and setting

The method of setting the tool offset in the offset interface is as follows:

Press【+Offset】soft key to enter the offset display interface.

Move the cursor to the position of the compensation number to be input.

Method 1: Press the page key to display the page where the compensation amount needs to be modified; press the arrow keys to move the cursor to locate the position of the compensation number to be modified.

Method 2: After entering the compensation number, press the search key to locate.

In any way, enter the compensation amount. Press the Enter key or the [Enter] soft key to confirm.

In any mode, enter the compensation amount, press the [+Input] or [-Enter] soft key, the system will automatically calculate the compensation amount and display it.

Note 1: When changing the tool offset, the new offset cannot take effect immediately. It must be executed after the H code or D code whose commanded compensation number is executed.

Note 2: The user can modify the tool compensation value at any time during the program operation, but to make it effective in the program operation in time, you must ensure that the modification is completed before running the tool compensation number.

Note 3: If the length compensation amount needs to be added to the relative coordinate value of the Z axis, just write the compensation amount behind the Z axis, and the system will automatically superimpose.

For example: input Z10, the compensation value is the current relative coordinate value of Z axis plus 10.

04 Conclusion

Through the above description, you can quickly understand and master the offset display, modification and setting, and effectively provide an intuitive and concise display interface, so that the customer is familiar with the operation, thereby ensuring the stability of processing and debugging.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|