|

Seek no vibration, no abnormal noise, and good surface finish when processing the workpiece;

The processing efficiency must be 15% higher than that of ordinary machine tools.

solution

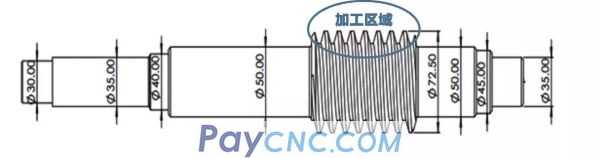

According to the requirements of the drawings for turning worms, large cutting force, and large worm pitch, Shenyang CAK5085 manual three-speed servo machine tool is used, and the torque is high during low-end processing;

A large worm cutter is used according to the worm pitch, which can meet the requirements of cutting worm;

The clamping method uses one clamp and one top to meet the large torque transmission of the workpiece and maintain stability;

According to the characteristics of the machine, such as strong rigidity and large torque, the forming tool is used for cutting.

Application effect

The processing time of a single piece of common equipment is 150 minutes, while the processing time of bed linen with Shenyang third-grade CAK5085 machine is 78 minutes. The processing time is short to meet the demand;

One clamp and one top are used for clamping, which is stable when the workpiece is transmitted with large torque, without shaking;

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|