Application of GSK980TDi CNC system lathe long axis knurling processing (for packaging equipment)

The Shenyang CAK50186 machine tool is equipped with a wide number system GSK980TDi. The workpiece is 1.8 meters long and 86mm in diameter with a hollow outer shaft knurling. The knurling depth is required to be 1mm, the overall depth is consistent, the grain is clear, and there is no disorder.

solution

Clamping method: one clip one top + follow knife holder;

Machine tool requirements: machine tool horizontal deviation ≤0.02mm;

The deviation between the height of the tailstock and the main shaft is less than 0.05mm, and the contact surface between the tail top and the workpiece is more than 3mm;

The center height of the double-wheel knurling cutter is absolutely within the center of the workpiece, and the deviation is within 0.05mm

Knife knives need to use layered and progressive swinging approach;

Coolant is in place.

Application effect

The outer circle of the workpiece is processed without vibration pattern, the depth of the knurling is 1mm, the overall pattern depth is consistent, the pattern is clear and free of disorder, which meets the customer's requirements.

02GSK980TDi CNC system is used for CNC transformation of ordinary lathes

The existing large lathes are all ordinary machine tools, which have low processing efficiency and need to be replaced with CNC lathes;

Compared with the new CNC machine, the old machine is a third of the price of buying the new machine;

It is planned to gradually complete the CNC transformation of the existing equipment in the factory.

solution

The machine tool grinding guide rail is scraped with plastic to restore geometric accuracy;

X / Z axis modified ball screw feed mechanism;

Install four-station electric knife holder;

Install hydraulic valve to control the spindle reverse rotation and brake;

Redesign and install the whole machine protection;

Configure GSK980TDi CNC system.

Application effect

After the transformation of the machine tool, it meets the accuracy inspection standard of the new machine to meet the needs of parts processing;

At present, this customer has transformed 5 machine tools.

03

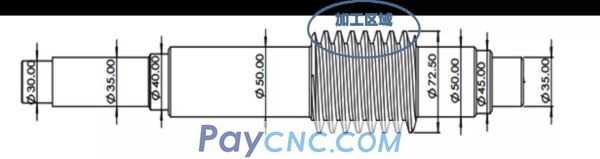

Application of GSK980TDi CNC system CAK5085 lathe worm

Need to use low speed, high torque, rigid machine tool to process the worm;

Seek no vibration, no abnormal noise, and good surface finish when processing the workpiece;

The processing efficiency must be more than 15% higher than ordinary machine tools.

solution

According to the requirements of the drawings for turning worms, large cutting force, and large worm pitch, Shenyang CAK5085 manual three-speed servo machine tool is used, and the torque is high when low-grade processing;

A large worm cutter is used according to the worm pitch, which can meet the requirements of cutting worm;

The clamping method uses one clamp and one top to meet the large torque transmission of the workpiece and maintain stability;

According to the characteristics of the machine, such as strong rigidity and large torque, the forming tool is used for cutting.

Application effect

The processing time of a single piece of common equipment is 150 minutes, while the processing time of bed pieces with Shenyang third-grade CAK5085 machine is 78 minutes. The processing time is short to meet the demand;

One clamp and one top are used for clamping, which is stable when the workpiece is transmitted with large torque without shaking;

There is no abnormal noise, no vibration knife, and good surface finish during processing to meet the processing needs.

|