The 218MC graphic display function adopts a more concise way. In order to prevent the scrap of the workpiece, the theoretical coordinate axis motion trajectory is generated from the motion information of the workbench during the trial processing of the machine tool, and then the actual motion trajectory is compared with the theoretical trajectory to monitor the processing . The graphic display back function was born. The graphic display function is described in detail below:

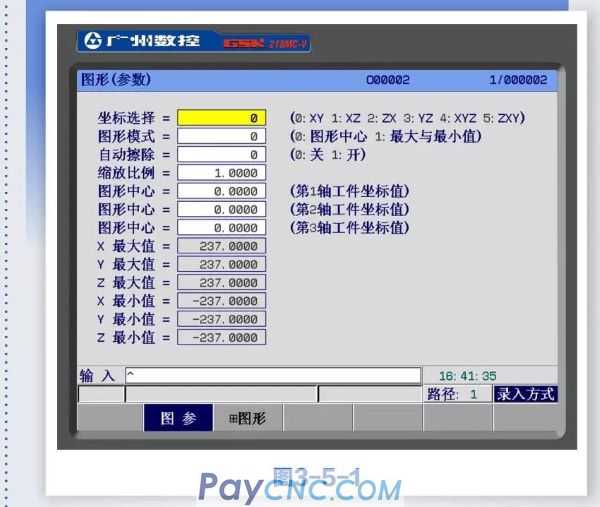

01 Press the graphic key to enter the graphic page. There are two display interfaces: [Picture Parameter] and [+Graphic], and the display can be switched by the corresponding soft key. See Figure 3-5-1 for details.

Figure parameter interface Press the [Figure parameter] soft key to enter the figure parameter interface, see Figure 3-5-1

The meaning of graphic parameters

Coordinate selection: There are 6 selection methods (0~5) for setting the drawing plane, as shown in the second line.

Graphic mode: Set the graphic display mode.

Auto Erase: When set to 1, after the end of the program, the program graphics are automatically erased when the next cycle starts.

Zoom ratio: Set the drawing ratio.

Graphic center: Set the workpiece sitting value corresponding to the LCD center under the workpiece coordinate system.

Maximum and minimum value: When the maximum and minimum values of the display axis are set, the CNC system automatically sets the zoom ratio and the center value of the graph.

X maximum: the maximum value in the X direction in the graphic display

(Unit: 0.0001mm/0.0001inch)

X minimum value: the minimum value of X direction in the graphic display

(Unit: 0.0001mm/0.0001inch)

Y maximum: the maximum value of Y direction in the graphic display

(Unit: 0.0001mm/0.0001inch)

Y minimum: the minimum value in the graphic display

(Unit: 0.0001mm/0.0001inch)

Z maximum value: the maximum value of Z direction in the graphic display

(Unit: 0.0001mm/0.0001inch)

Z minimum value: the minimum value of Z direction in the graphic display

(Unit: 0.0001mm/0.0001inch)

Graphic parameter setting method

a. Move the cursor to the parameter;

b. Type the corresponding value according to the actual requirements;

c. Press the Enter key to confirm.

Graphic interface Press the [+Graphic] soft key to enter the graphical interface (see Figure 3-5-2).

In the graphics page, you can monitor the machining track of the running program.

Press the [Start] soft key or S key to enter the state of starting drawing, at this time the number moves to S; before drawing starts;

Press【Stop】soft key or T key to enter the stop drawing state, at this time the number moves to T: before drawing stops;

Each time you press the [Switch] soft key, the graph switches in the coordinate display corresponding to 0~5.

Press【Clear】soft key or delete key to clear the drawn graphics.

02 Conclusion

Through the above description, you can quickly understand the graphic display function and effectively provide an intuitive and concise display interface. This function will monitor the processing track of the running program on the graphic page to ensure the stability of processing and debugging.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|