Production milling machine processing time 1-5 minutes, production line production capacity: 350 pieces / hour;

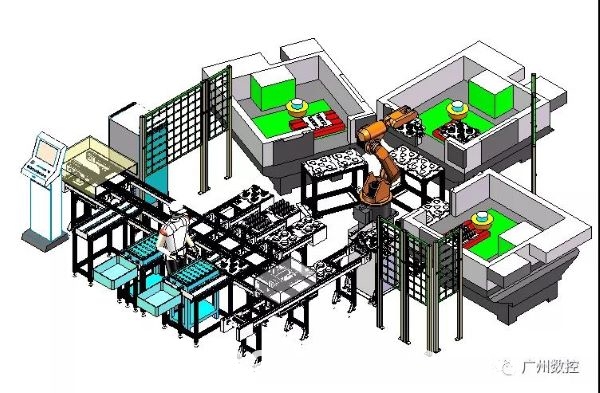

The robot replaces the manual, and completes the production of the workpieces between the three CNC milling machines, the pallet clamps, and the loading and unloading bins;

Three kinds of products are mixed at the same time, special pallets and milling machine processing fixtures; robotic fixtures have strong versatility, and it is necessary to realize mixing and grabbing of different products.

solution 1 set of RB15L handling robot, 1 set of custom flexible hand grip, 3 sets of machine tool fixtures, 1 set of double speed conveying line, 3 sets of temporary storage positioning device, 1 set of tray cleaning device, 3 sets of CNC milling machines, complete blanks Material, milling plane, drilling and tapping, cleaning of workpieces and finished products are collected centrally; The robot hand grip adopts the customized flexible design, which is compatible with all the trays to grab, accurately locate and have the abnormal fall arrest function of the gas cutoff and power supply, ensuring stable production of loading and unloading. The double-speed chain conveying system is used to sort and convey the pallet clamps and the pallet turnover buffer, so that workers can collect materials intensively; Applying FDI automatic identification system technology, automatic sorting and conveying of different pallets, automatic identification of pallet processing workpieces and corresponding loading station.

Application effect

Adopting a flexible flexible manipulator design, solving the problem of multi-model and small-batch production in the same production line with less manufacturing cost;

The robot replaces the manual, and realizes the one-to-three numerical control machine tool to operate at any time for 24 hours, and stably complete the work task;

The robot operation works closely with the CNC milling machine and the double speed chain conveying system, and the work is stable, maximizing production efficiency and reducing production and operation costs.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|