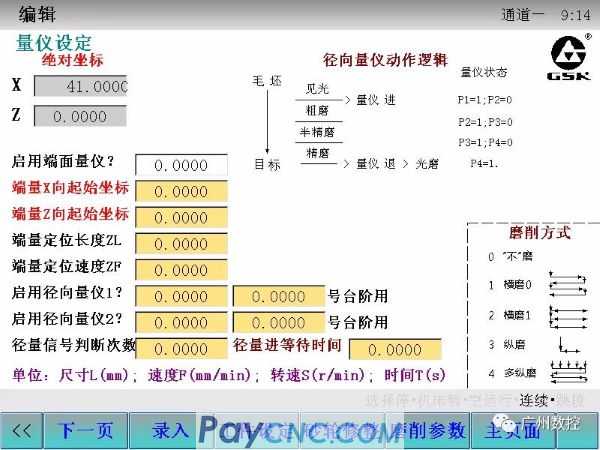

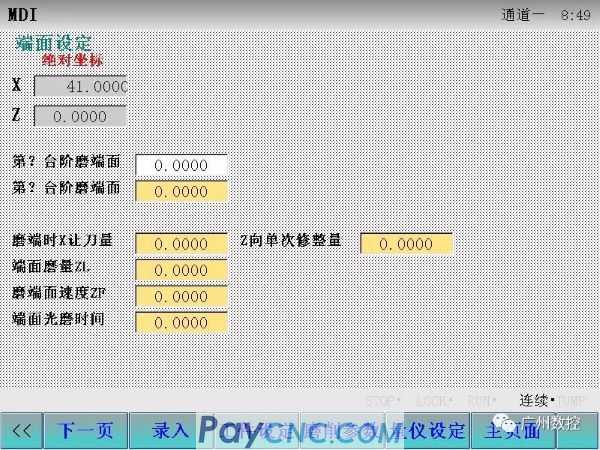

Menu interface input;

The workpiece is clamped in one time;

The processing precision is controlled within ±0.004mm, and the batch consistency is better;

With automatic grinding wheel and automatic compensation function.

solution

It has a five-axis RTCP function to support the processing of complex parts;

With dedicated 3+2 positioning processing function instructions;

B-spline curve can effectively filter and smooth the tool path, improve processing efficiency and improve surface finish;

Fully closed loop equipped with HEIDENHAIN encoders.

Application effect

The trigger type tool setting device can automatically set the workpiece coordinate system and the machining reference point before the numerical control machining process;

The outer diameter measuring instrument can detect and control the key size and position coordinates and its precision between processing steps;

With the parameter parameter programming, it can be used for all-round control functions such as grinding process program change, workpiece quality management, machine tool status monitoring, fault self-diagnosis and abnormal alarm. The interface input is concise and convenient.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|