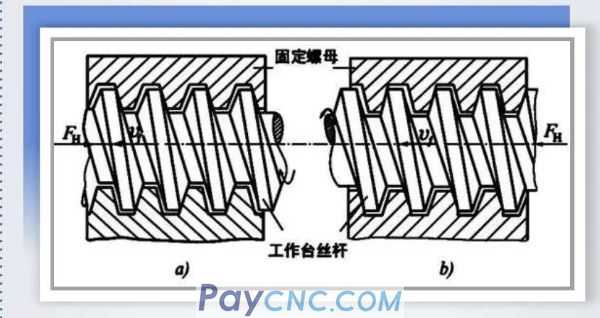

There are backlashes in all parts of the CNC machine tool feed drive chain, such as gear drive, ball screw nut pair, etc. Backlash is one of the factors that affect the machining accuracy. When the CNC machine tool table is commutated in its movement direction, the servo motor is idling due to the existence of the backlash and the table does not actually move, which is called stall. If the value of the backlash is small, there is no need to take any measures for the impact on the machining accuracy; if the value is large, the stability of the system is significantly reduced, and the machining accuracy is significantly reduced, especially the curve processing, which will affect the dimensional tolerance Consistency with the curve, at this time, the backlash must be eliminated or compensated to improve the processing accuracy.

Backlash compensation can be set to compensate the amount of backlash of the machine tool at a fixed frequency or in speed up and down. It can be measured with a dial indicator, dial indicator or laser detector. The backlash compensation must be accurately compensated to improve the processing accuracy. The backlash compensation of the 218MC system provides customers with convenient, concise and intuitive operation methods. The setting method of backlash compensation is introduced in detail below:

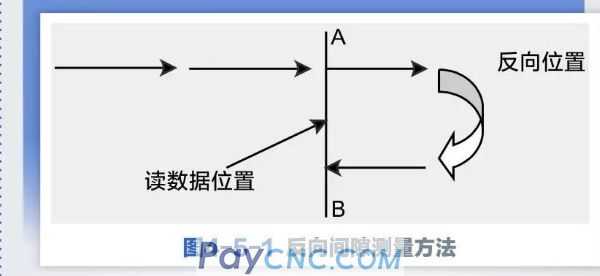

It is strongly discouraged to use MPG or single-step method to measure the direction gap of the screw. It is recommended to measure the direction gap as follows:

Edit program:

O0001:

N10G01G91X1F800;

N20X1;

N30X1;

N40X-1;

N50M30;

Before the measurement, the backlash error compensation value should be set to zero;

Run the program in a single segment, find the measurement reference A after positioning twice, record the current data, and then run in the same direction for 1mm, and then run in the reverse direction of 1mm to point B to read the current data.

Backlash error value = | data recorded at point A-data recorded at point B; enter the calculated data into the corresponding system parameters.

Data A: The data of the dial indicator is read at A;

Data B: The data of the dial indicator is read at B;

Pulse equivalent: 1 micron

Note 1: The data parameters P190~P194 set the direction gap compensation amount of each axis.

Note 2: The data parameters P195~P199 can set the direction gap compensation method and compensation frequency.

Note 3: To ensure the accuracy of the machine tool, the backlash can be re-checked after the machine tool is used for 3 months.

02 Conclusion

In summary, the backlash error compensation is an important means to ensure the machining accuracy of CNC machine tools. The system parameter compensation method does not affect the preparation of the machining program, is easy to operate, simple and clear, and has a certain effect within a certain range. After the backlash value is entered into the CNC system, the CNC machine tool will automatically compensate this value during processing. Quickly master the setting method of the backlash compensation color. By this method, the backlash is measured, which can effectively and accurately compensate, so as to improve the accuracy of processing and ensure the stability of processing and debugging.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|